As globalized food trade has become more common in recent years, improved screening methods combined with food inspection investigations have put a large amount of pressure on the food and beverage industry to improve quality assurance and control. This pressure led to the FDA Food Safety Modernization Act (FSMA), which aims to ensure the U.S. food supply is safe by shifting the focus of federal regulators from responding to contamination to preventing contamination.

Considering recent events, the adulteration of food products—which is defined by the FDA as food bearing or containing any poisonous or deleterious substance which may render it injurious to health—continues to be a major concern in food testing. New products such as dietary foods, 'organic' foods, new botanical ingredients, nutraceuticals, and dietary supplements have increased the need for quality and safety testing of food products.

Analysis is performed at all stages of food production, including the intake of raw materials, processing, and final product packaging, to ensure the absence of chemical contaminants (e.g., melamine, acrylamide), metals (e.g., lead, mercury), natural toxins (e.g., mycotoxins), veterinary drugs residues (chloramphenicol…), pesticides, and disease-causing organisms (e.g., Salmonella).

The automation of SPE methods is in high demand due to the need to improve reproducible test results and satisfy the increasing demand for greater sample load analysis.

This analysis must meet a variety of legislative requirements as well as instill consumer confidence. Collaboration between laboratories is required to ensure harmonization and validation of analytical procedures at a global level. Agencies such as AOAC International, the World Health Organization (WHO), the International Organization for Standardization (ISO), as well as various federal and state agencies play a major role in the harmonization of analytical methods used by the food and beverage industry.

A number of different analytical techniques are used in chemical food safety testing. The types of techniques seen most often are bioassays, such as enzyme-linked immunosorbent assay (ELISA), advanced instrumental techniques, including infrared (IR) spectroscopy, nuclear magnetic resonance (NMR), or mass spectrometry (MS). These different analytical techniques are solutions for the variety of samples that largely differ in complexity as food matrices encompass a wide range of forms (solids, semisolids, suspensions, and liquids).

There is a clear trend toward finding new ways to analyze as many analytes in a single run as possible. The separation techniques coupled with high resolution mass spectrometry are increasingly employed in methods that allow simultaneous analysis of numerous multi-class residues and contaminants, such as pesticides, mycotoxins, plant toxins, or adulterants.

These chemical compounds have different properties and must be removed from the remaining chemicals that make up a food or beverage. Because of this, sample preparation is almost always required prior to determination (analysis) for the analyte of interest.

SPE is widely used for extraction and post -extraction clean -up of these complex matrices. If the food is in solid form, it is chopped or blended with an organic solvent prior to performing the SPE extraction step. If it is in liquid form already, it can be extracted directly using an SPE cartridge or may be diluted prior to extraction. If the sample is very complex, several SPE steps may be performed – the first step for extraction and a second to further clean up the sample.

Reliability and reproducibility are key for the growth of SPE in this industry. The automation of SPE methods is in high demand due to the need to improve reproducible test results and satisfy the increasing demand for greater sample load analysis. The most common automation application applied in the contemporary food testing laboratory is liquid handling, such as dilution, derivatization, pH adjustment, liquid and solid extraction, mixing/stirring, and evaporation.

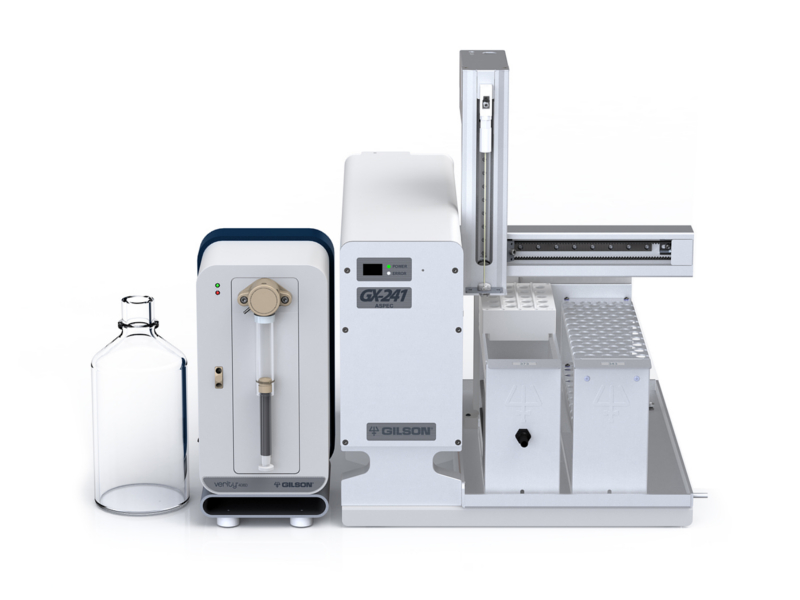

Gilson provides a broad array of automated SPE products to meet the discussed needs of the food and beverage industry. These include the ASPEC® 241 System, ASPEC® 271 System, and ASPEC® 274 System.

These systems have the capability to handle both small and large sample volumes. This is a key benefit for handling a wide variety of food and beverage matrices along with advanced SPE protocol compliance. These systems provide sample preparation and clean -up of high reproducibility.

Gilson’s mobile rack option enables multiple fraction collection and cleanup in the same run, while positive pressure technology ensures more reproducible flow rates and recoveries. Additionally, the high- quality rinse station guarantees less sample- to-sample contamination. Finally, Gilson’s easy -to- use TRILUTION® LH Software simplifies application setup and method development while combining basic liquid handling (dilution, filtration, mixing, and liquid extraction) and SPE automation on the same platform.